Facility

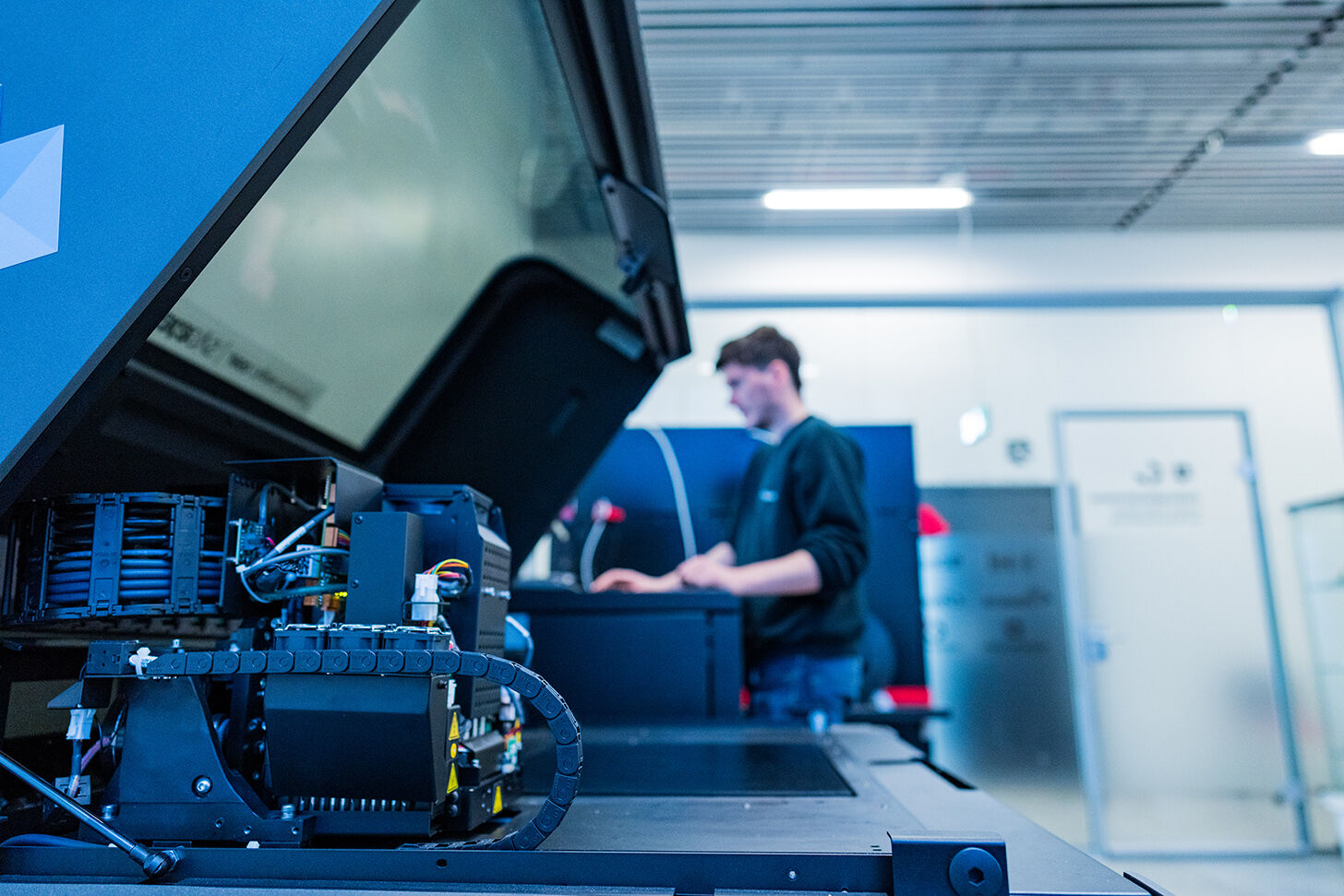

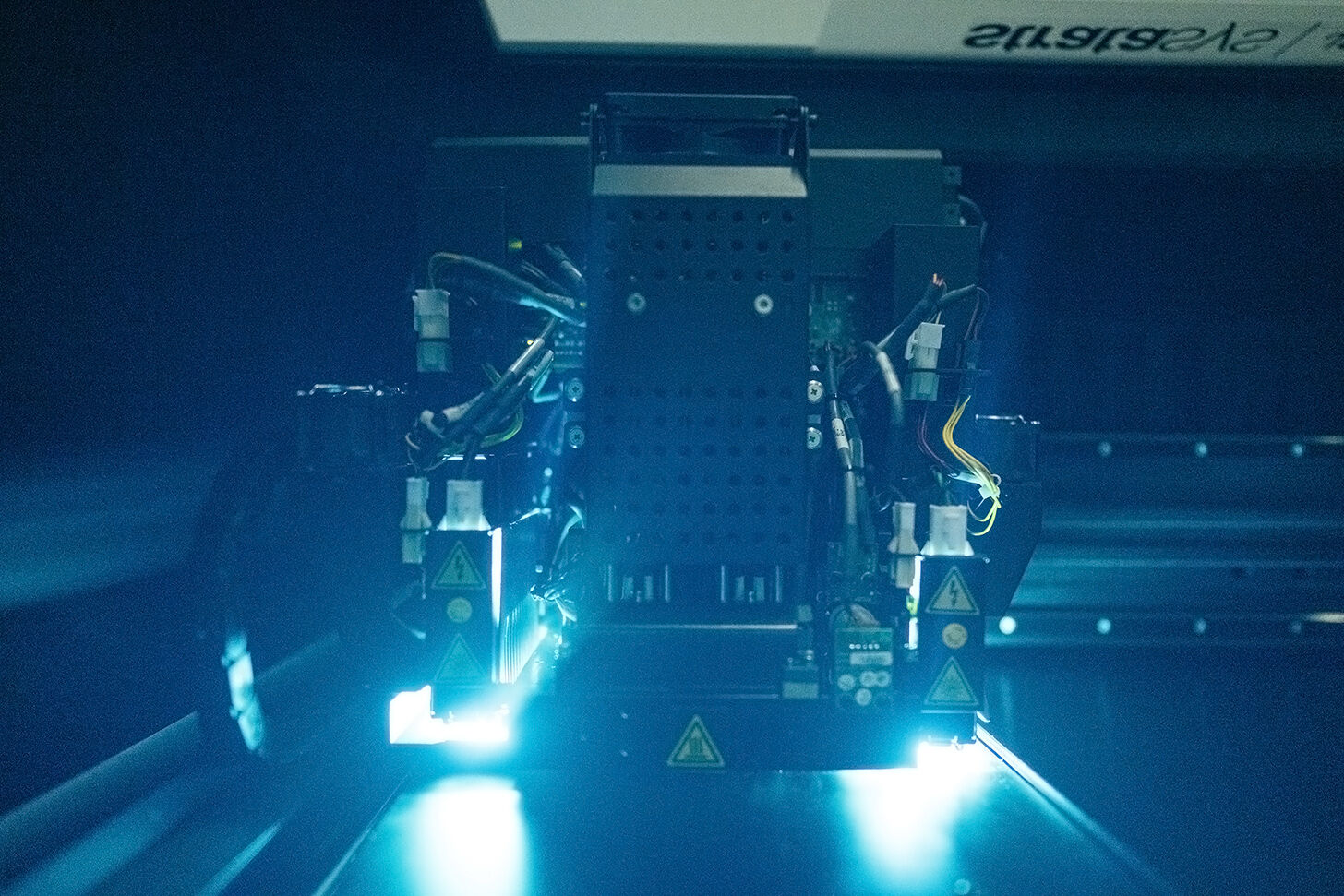

The ICAAM core facility is a J850 Digital Anatomy 3D Printer, a cutting-edge technology able to print high-resolution models in a wide variety of materials and colours. It works like an inkjet printer, but PolyJet 3D printers jet tinny droplets of plastic instead of jetting drops of ink. A UV light instantly cures the plastic, solidifying it, so complex models take shape layer by layer.

The J850 printer can build multi-material parts, soft, rigid, clear, and colourful. With this printer, it is possible to adjust material properties, like heat resistance and durability. The J850 printer can print unique material combinations based on innovative materials to create realistic models that vary in softness, flexibility, and density to mimic native tissue and bone behaviour, such as organs that behave like the real thing when force is applied, vascular complex structures and bone structures. This reduces the need to use animal models. The printer can be used for surgical preparation, medical training, and medical device testing.

The main applications where we will employ this technology are

- Create smooth, detailed prototypes that convey the final product aesthetics.

- Produce accurate moulds, jigs, fixtures, and manufacturing tools.

- Achieve complex shapes, intricate details, and delicate features.

- Incorporate the widest variety of colours and materials into a single model.

- Complex anatomies and cardiovascular systems

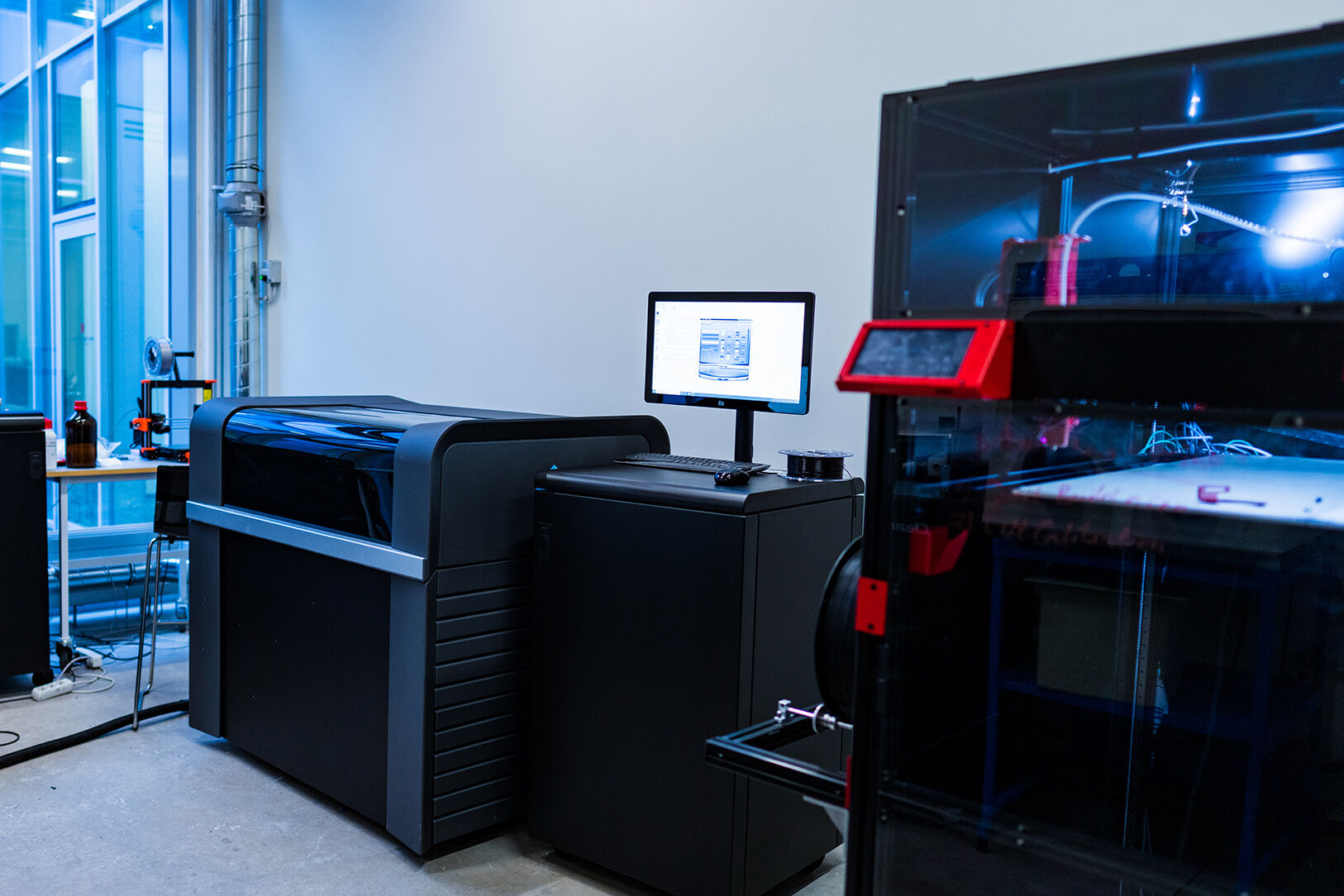

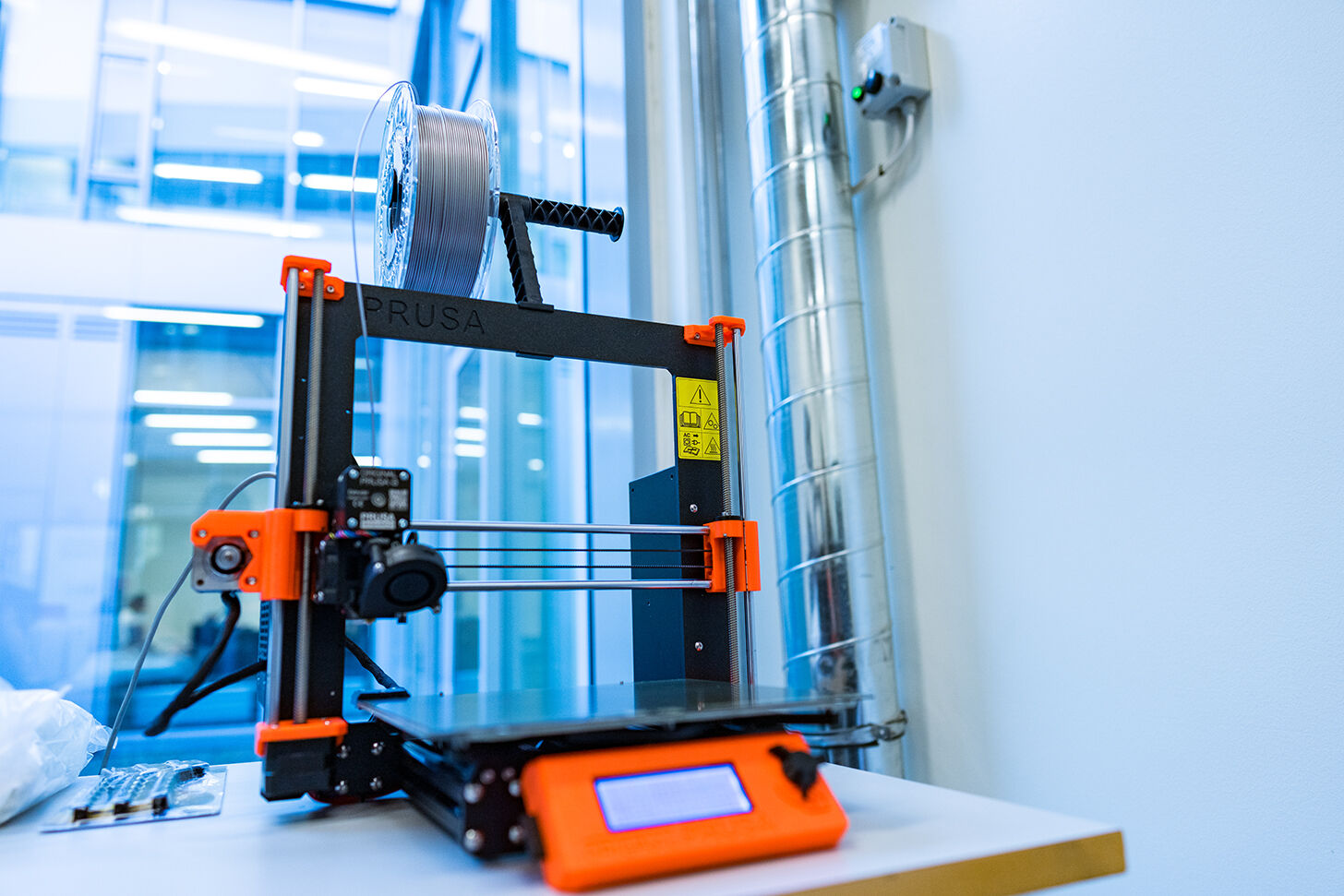

Additionally, to the j850, ICAAM is equipped with another PolyJet 3D printer' called Connex3 Objet260 and a large-size printing volume( 1,010 x 1,010 x 1,010 mm) FDM printer called Modix BIG-meter.

The Additive Manufacturing Lab is also equipped with a portable professional 3D scanner called Artec Leo, this device allows wireless acquisitions and it is fully standalone and designed to make scanning precise and effortless.

Complementary a powerful workstation enables, 3D design, meshing and computational analysis such as FEA/CFD for product design and optimisation.